Advantages of Rack & Roll pallet roller conveyors:

- Designed for longitudinal or transverse pallet handling

- High availability

- Constant speed control by the spring-mounted brake rollers (independent of operating condition and load)

- Reliable functionality at all times, even with pallets of different weights from 80-1,500 kg

- Loading, intermediate and unloading conveyor elements with full width or multiple roller tracks as required

- Integration in all conventional pallet racks

- The pallet separation mechanism allows every pallet to roll to the end stop.

- Pallets weighing 200-1,000 kg can run mixed in the same conveyor lane. Guaranteed.

- Zero pressure unloading of the pallets due to the mechanical or pneumatic separating devices.

- Particularly robust construction to prevent damage by handling equipment.

- All components suitable for use in freezer conditions.

- Unloading with a hand pallet truck possible due to the triple roller track unloading element with reduced 66mm overall height

- In the Rack & Roll test centre we test and develop solutions for your special pallets.

- Operationally safe solutions available for mesh box pallets, metal pallets, plastic pallets, half pallets and numerous special pallet designs.

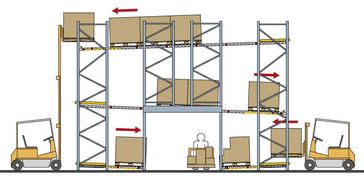

FUNCTIONALITY OF THE PALLET ROLLER CONVEYORS

- Separator flap is raised to indicate that the separator is open.

- The first pallet on the roller conveyor can roll to the unloading position.

- In the area of the unloading element, the first pallet accelerates to create a gap from the following pallets.

- The speed of following pallets is controlled by the brake rollers before the separator bar.

- The weight of the first pallet pushes the separator pedal down and the separator bar is activated.

- The following pallets are thus stopped at the separating bar.

- When the front pallet is removed, the separator pedal is raised again to release the following pallet to roll forward into the removal position.

FIFO System

PUSH-BACK OR FIFO ROLLER CONVEYORS

CROSSWAYS OR LONGITUDINAL TRANSPORT

- Standard is longitudinal transport of the pallets on roller conveyors

- New development: Crossways transport of pallets on roller conveyors

- Enables easy manual picking as the depth of the pallet is 800 / 1000mm deep

- Two / Three roller tracks minimise deflection and maximise operational safety.

- Super running properties due to short roller pitch and length

- Convenient removal of pallets due to separating device with foot release

- Easy floor cleaning between the lanes

ORDER PICKING ROLLER CONVEYORS

In many cases, the floor mounted roller conveyors are designed so that goods are manually picked from the first pallet.

This can be done with individual, free-standing floor mounted conveyors, on lowest level of a multi level rack or in picking tunnels of a larger bulk storage flow rack.

ROLLER CONVEYORS AS STOCK BUFFERS IN PRODUCTION

Our roller conveyors are often used as stock buffers within production, for example between two processing stations. This makes it easy to maintain the production sequence of different work stations.

ROLLER CONVEYORS IN THE SHIPPING DEPARTMENT FOR STAGING OF LOADS

A standard application is also in the shipping area. Here, the pallets are picked from storage racks and staged on roller conveyors for loading onto the truck. For example, in one or two lanes of roller conveyors, a whole truck load is prepared for loading in a very small space. When the truck arrives, the dispatch operative can quickly remove the pallets from the lane and load them in the truck, while the other pallets roll forward for removal. The loading process is noticeably quicker and the pallets are systematically prepared in advance of loading. This can increase the efficiency in the shipping department by reduced manpower or greater capacity to load more trucks in the same time period.

MULTI XXL HEAVY LOAD ROLLER CONVEYORS

- For steel pallets and stillages with small plate feet or narrow runners

- Up to 3000 kg per individual loading unit, i.e. also lattice boxes stacked on top of each other

- Very smooth running properties due to precision high quality ball bearings