FLOW RACKS FOR ORDER PICKING - THE ADVANTAGES:

- Extremely light and robust construction, also for tough workshop assembly environments

- Adaptable with a few simple movements

- Stable screw/plug-in connections for construction

- 2 standard continuous frame types

- (Combi and heavy duty/XXL) to choose from, load capacity up to 300 kg/sqm

- Adjust the number of flowshelves according to the stored goods (20 mm adjustment pitch for height and inclination)

- Field widths and depths freely selectable

- Individual design of the shelf front (e.g. gripping handle) with a range of components

- Extremely resilient roller tracks with best roller running properties

- Simple and individual integration of driven conveyor technology

- Integration of the flow frames in all conventional pallet rack brands possible

- Multi-storey order picking systems with intermediate platforms are possible

- Extremely long channel depths of up to 20 metres possible

- Numerous accessories on request

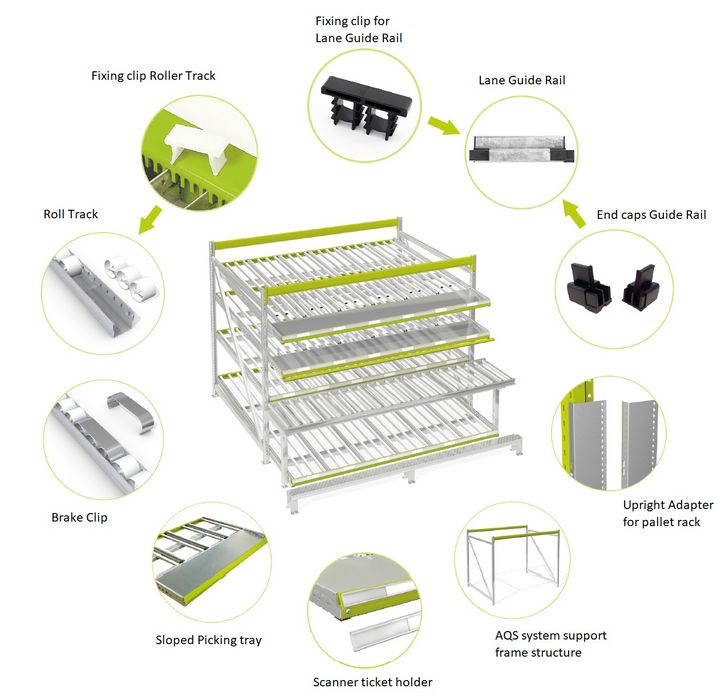

ACCESSORIES FOR SMOOTH HANDLING

POWERFUL COMPONENTS FOR PICKING AND STAGING

At AQS, we always have the entire system in mind. That's why we match our components precisely to our customers' production and conveying requirements. The result is a high-performance portfolio of parts and accessories that makes your life much easier in the internal handling of goods. Your advantage: the highest possible space efficiency, fast stock turnover and seamless provision with low maintenance at the same time.

FLOW FRAME

TYP COMBI

- For small to medium loads up to max. 170 kg/sqm

- Maximum field width: 2,800 mm

- Very flexible and inexpensive variant, yet rigid construction due to corner screw connections

- Easy to assemble due to tool-free installation of the rollers and guide rails

- Easy and quick (tool-free) change of the channel widths

- The roller and guide rails are accommodated in slotted front and rear beams (with protection against bowing).

- Lateral adjustment increments of approx. 7.5 mm

- Continuous side panels with sloped order-picking shelves available (inclination: 6 & 15°)

- Special designs on request

TYPE HEAVY LOAD

- For particularly high loads (300 kg/sqm)

- Maximum field width: 3,800 mm

- All components completely screwed together

- Usually bolted to shelf uprights or adapters

- Equipped with roller rails and guide rails like Combi frames

- Continuous side panels with order-picking shelf available(inclination: 6°)

ACCESSORIES FOR FLOW FRAMES

FOOT STEP

- Better access to the upper flow levels

- Variable heights and widths

- AQS anti-slip punching or anti-slip coating

- Mounted on shelf supports or on the floor

CONVEYOR SUPPORT LEGS

- For supporting driven or non-driven roller conveyors (along the flow rack)

- Made of uprights with adjustable feet and support brackets

- Support brackets individually perforated

- Special designs on request (e.g. for overhead waste box conveyors)

SCANNER TICKET HOLDER

- Glued to front and rear beams

- Labelling the channels by inserting labels

- Standard height: 30/40 mm

HAND GRIP RAIL

- Used in conjunction with steps (for operator safety)

- Attached to the upper flowshelf

- Material: tubular steel, powder-coated surface

LANE GUIDE RAILS

- For lateral separation and guidance of the stored goods

- Maximum part length: 6,000 mm to 20,000 mm possible

- Tool-free adjustment of the channel width

- Material: galvanised, torsion-resistant sheet steel profile

- Also available as a divider strip in tubular design, diameter 20 mm, length up to 2,500 mm

- Special guide rails for special cases

WIRE LANE ENTRY GUIDES

- For lane separation at short flow depths, 400 mm long

- Require special underbeam and back beam, with perforations

CONNECTING TO AQS SUPPORT FRAME SYSTEM

AQS SUPPORT FRAME

- Plugged into keyhole of AQS uprights

- Continuous support for the side profiles

AQS SUPPORT FRAME SYSTEMS

- Flexible screw-in modular system of uprights, diagonals and connectors

- C-profile components, galvanised

- Upright heights: 1,800, 2,120 or 2,520 mm (other dimensions on request)

- Connection of the support frames by crossbeams, maximum bay width: 3,800 mm

- Powder-coated crossbeams

- Keyhole on the side of frame uprights for flowshelf adjustment in 20 mm increments

- If required, crossbeams with bolted connection plates (e.g. for mobile shelving)

UNIVERSAL UPRIGHT ADAPTER 230 MM

- Fits on 90 % of all racking systems

UPRIGHT ADAPTER

- For connecting the AQS flowframes on to all types of rack uprights

- Designed to suit the respective rack system

- Quick assembly

- Standard height: 1,800 mm

- Keyhole on the side (adjustment in 20 mm increments)

ROLLER TRACKS

STANDARD ROLLER TRACKS

- Torsion-resistant, self-stabilising profile made of galvanised steel coil

- Lengths accurate to the nearest mm according to customer requirements, maximum single length: 6,000 mm but up to 20,000 mm possible with connected sections

- Roller pitch 33 mm: with best running properties due to the geometry (32 mm diameter roller)

- Optional Roller pitch 28 mm: for the smallest stored goods

- Rollers can be used mixed, overall height: generally 36 mm

- Material: high-quality plastic (natural white)

- Standard rollers are also suitable for freezer conditions.

- ESD version available (highly conductive rollers)

- Bearing on steel axles for longer service life, quiet running and high load capacity (12 daN)

- Easy exchange of rollers without any tools

- Millions in use worldwide

SPRING ROLLER MOUNTING CLAMPS

- For integrating the AQS roller tracks into other shelving systems

- Material: spring steel

BRAKE ROLLER

- Weight range unique on the market

- Easy assembly by exchanging with the standard rollers

- Enable diverse applications, e.g. sorter buffers, supermarket applications or deep flow racks, especially with a steep incline

BRAKE CLIP

- Clipped over 3 rollers

- For braking the stored goods before the end stop (Attention: no restart of the goods rolling)

- Material: galvanised spring steel

ANTI-ROLLBACK DEVICE

- Used when having automated container handling by a stacker

- Preventing collisions between stored goods and the automated handler

- Material: plastic, mounted on steel axles

- Special design of aluminium/steel combined (for toughest use and special heights)

END STOPS

- Eliminates the requirement for a full front stop beam when handling of containers is required between the roller tracks

- Directly inserted with steel axles in roller tracks

- Reduces the rolling velocity of containers with a gradual braking surface

- Use in flow channels of automatic small parts warehouses (miniload) or for direct mounting of rollers on beams in pallet racks

- Material: plastic